The Rhino Linings Protective Coatings Division specializes in developing high and low pressure 1:1 and 2:1 mix ratio polyurea and polyaspartic formulations with unique physical properties and chemical advantages to meet the application requirements of virtually any application. Rhino Linings coatings provide a durable monolithic, protective barriers that protect against abrasion, moisture, corrosion, and impact. These coatings are used to increase the life of a variety of industrial and commercial materials, and to be applied to many different substrates.

Our impermeable linings and coatings conform to any shape and can be built up to any thickness. Rhino Linings products are engineered to last, ensuring your equipment or assets are protected from the hazardous field conditions.

Rhino Linings is a leading provider of industrial coatings, offering innovative solutions that provide reliable protection for a wide range of applications. With their durable and versatile coatings, Rhino Industrial Coatings offer numerous benefits, making them the go-to choice for industrial environments.

Benefits of Rhino Coatings Linings

Durability

One of the key benefits of Rhino Industrial Coatings is their exceptional durability. Designed to withstand harsh conditions, Rhino coatings provide reliable protection against abrasion, impact, corrosion, and chemicals. This durability ensures that machinery, equipment, and structures remain protected, reducing the risk of damage and extending their lifespan.

Chemical-Resistant

In addition to durability, Rhino Industrial Coatings are highly resistant to a variety of substances, including chemicals, oils, fuels, solvents, and acids. This resistance makes them ideal for industries such as manufacturing, oil and gas, agriculture, automotive, and more. With Rhino coatings, industries can confidently store, transport, and process materials without worrying about leaks, spills, or corrosion.

Versatility

Another advantage of Rhino Industrial Coatings is their versatility. Designed to adhere to a variety of surfaces, including metal, concrete, wood, and fiberglass, Rhino coatings can be applied to an array of equipment, structures, and surfaces. Whether it’s lining storage tanks, protecting pipelines, coating truck beds, or providing non-slip surfaces, Rhino Industrial Coatings offers a versatile solution for countless applications.

Why Choose Rhino Industrial Protective Solutions?

High-Quality Products

One of the main reasons why customers choose Rhino Industrial Coatings is their reputation for quality. With decades of experience and a commitment to innovation, Rhino Linings has become a trusted name in the industry. Our industrial coatings undergo rigorous testing and meet industry standards to ensure that they deliver reliable performance and superior protection.

Easy Application

Furthermore, Rhino Industrial Coatings are known for their ease of application. Available as spray-on coatings or as trowel-applied systems, Rhino coatings offer a seamless and uniform finish without the need for joints or seams. This ease of application not only saves time and labor costs but also ensures consistent and reliable protection.

PRODUCTS

POLYURETHANE & POLYUREA

Spray Polyurethane Foam Insulation

Spray Polyurethane Foam Insulation is a high-performance insulation solution that provides superior thermal insulation and air sealing properties. Its ability to conform to irregular surfaces makes it ideal for insulating walls, roofs, and crawl spaces, resulting in energy-efficient and comfortable spaces.

ACRYLIC & SILICONE

Acrylic & Silicone

Acrylic & Silicone coatings are protective coatings that offer excellent weather resistance, UV protection, and waterproofing capabilities. They are commonly used for sealing and protecting roofs, decks, and concrete surfaces, providing durable and long-lasting solutions for various applications.

EPOXY COATINGS & LININGS

Epoxy Coatings & Linings

Epoxy Coatings & Linings are durable and chemical-resistant coatings that are commonly used in industrial settings. They provide a high-gloss finish and excellent protection against abrasion, chemicals, and impact, making them ideal for floors, tanks, and other surfaces subjected to harsh conditions.

POLYASPARTIC FLOORS

Durable Coating & Crack/Hole Repair

Durable Coating & Crack/Hole Repair products are designed to repair and restore damaged surfaces, including concrete, metal, and wood. These products offer excellent adhesion, flexibility, and durability, ensuring a seamless and long-lasting repair solution for cracks, holes, and other surface imperfections.

CIPP, COMPOSITES & VARTM

Cured In-Place Pipe, Composites, & Manufacturing

Cured In-Place Pipe (CIPP) is a trenchless technology used to repair and rehabilitate pipes without the need for excavation. It involves inserting a flexible liner into the existing pipe, which is then cured in place to create a new, structurally sound pipe. CIPP is a cost-effective and efficient solution for repairing underground pipes and sewers.

MACHINES

Spray Machines

Spray Machines are specially designed equipment used to apply coatings, insulations, and linings in an efficient and controlled manner. These machines ensure uniform application and proper coverage, saving time and labor during the application process.

PRIMERS & TOPCOATS

Primers & Topcoats

Primers & Topcoats are coatings specifically formulated to enhance adhesion, improve coverage, and provide protection for surfaces before the application of the final topcoat. Primers create a strong bond between the substrate and the coating, ensuring long-lasting performance, while topcoats offer additional protection and aesthetic appeal to the surface.

Applications

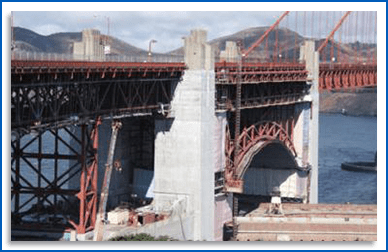

CONSTRUCTION EQUIPMENT

Durability, water resistance, energy efficiency

Rhino Industrial Coatings are commonly used to protect and extend the lifespan of construction equipment, such as bulldozers, excavators, and dump trucks, by providing a durable and abrasion-resistant coating that withstands the rigors of daily use.

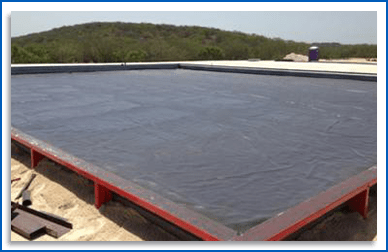

CONTAINMENT

Smart Investments to Protect Resources

Rhino Industrial Coatings are also ideal for containment applications, such as secondary containment areas for chemical storage. With their excellent resistance to chemicals and their ability to prevent leaks and spills, Rhino linings ensure environmental safety and compliance.

MILITARY BLAST & MITIGATION

Curtail Shrapnel & Deflect Energy

In the military sector, Rhino Industrial Coatings play a crucial role in blast and mitigation applications. These linings provide critical protection against blasts, fragments, and shock waves, enhancing the safety and survivability of military vehicles, structures, and equipment.

MINING

Protect Mining Equipment

In the mining industry, Rhino Industrial Coatings are commonly used to line chutes, hoppers, and other high-wear areas, providing superior abrasion resistance and preventing material buildup. This prolongs the life of equipment, reduces maintenance costs, and improves operational efficiency.

OIL & GAS

Time-Tested Products That Provide Long-Term Performance

For the oil and gas industry, Rhino Industrial Coatings offer excellent corrosion protection for pipelines, storage tanks, and offshore structures. These linings resist the harsh effects of chemicals, moisture, and UV exposure, preserving the integrity of critical infrastructure and ensuring safe and reliable operations.

TRANSPORTATION & EQUIPMENT

VOC-Free and Designed To Reduce Maintenance Costs

Rhino Industrial Coatings are also widely used in transportation and equipment applications. From trailer beds to vehicle undercoatings, Rhino linings protect against impact, rust, and corrosion, providing additional durability and extending the life of transportation assets.

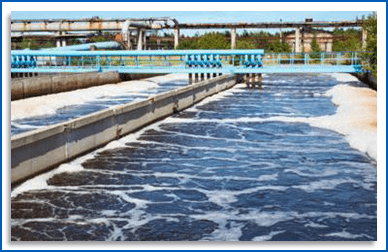

WATER-WASTEWATER

Excellent Stability for Immersion Applications and Chemical Resistance

In the water and wastewater industry, Rhino Industrial Coatings offer corrosion and chemical resistance for concrete structures, pipelines, and treatment facilities. These linings prevent deterioration and contamination, ensuring the longevity and efficiency of water and wastewater management systems.

BECOME A RHINO LININGS CONTRACTOR TODAY

Rhino Industrial Coatings offers outstanding durability, chemical resistance, versatility, and ease of application. With their proven track record of quality and a wide range of applications, Rhino coatings are the ideal choice for industries requiring reliable and long-lasting protection. Whether it’s protecting equipment, structures, or surfaces, Rhino Industrial Coatings provide the peace of mind that comes with superior industrial-grade solutions. Inquire about becoming a Rhino Linings contractor today!